visTABLE - with our use case to a new layout

Material flow optimization and layout planning with visTABLE

Home > Use Case: Layout planning in visTABLE

Planning of a factory for compressors in visTABLE

On the basis of a greenfield factory planning for a compressor manufacturer, we would like to take a closer look at the generic use of Plavis visTABLE. The company is a medium-sized manufacturer of piston and screw compressors. The process is a holistic process, which represents the entire internal value chain in the company. The production refers to the housing or the basic body of the compressors, the injection molding of plastic housings and the production of turned parts. All other parts and components are purchased parts that are directly incorporated into the assembly of the finished products. Depending on the type of compressor, different processing steps are carried out at different stations.

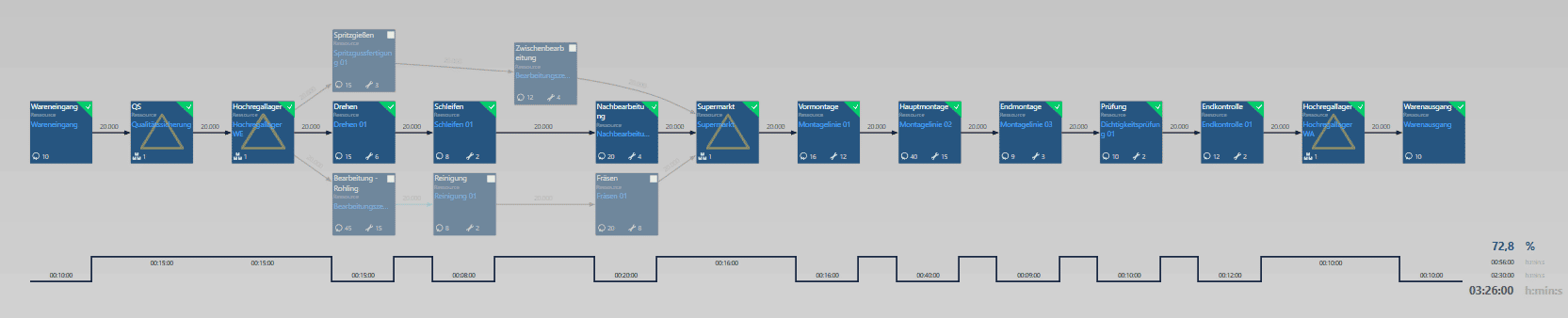

Design of the value stream in visTABLE

Possible reference sources for required values and information are routings, production orders, production programs and bills of materials. These can be used, for example, to determine process steps, material flows or the number of machines required. A process was created on the basis of this data collection. For this purpose, value streams of the individual compressor types were created on the basis of the process, which are all identical in their basic structure. The only differences are in the selection of the producing machines and the selection of the corresponding assembly stations. The figure shows an example of such a value stream based on the process for manufacturing a piston compressor.

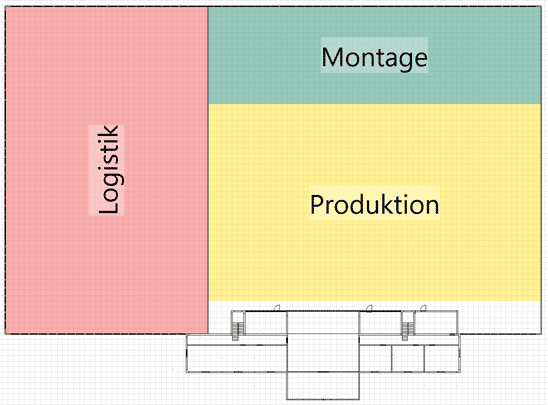

Dimensioning the surfaces and defining the structure

The areas were dimensioned on the basis of the future production program and capacity planning. For this purpose, they were first divided into the functional areas of logistics, production and assembly.

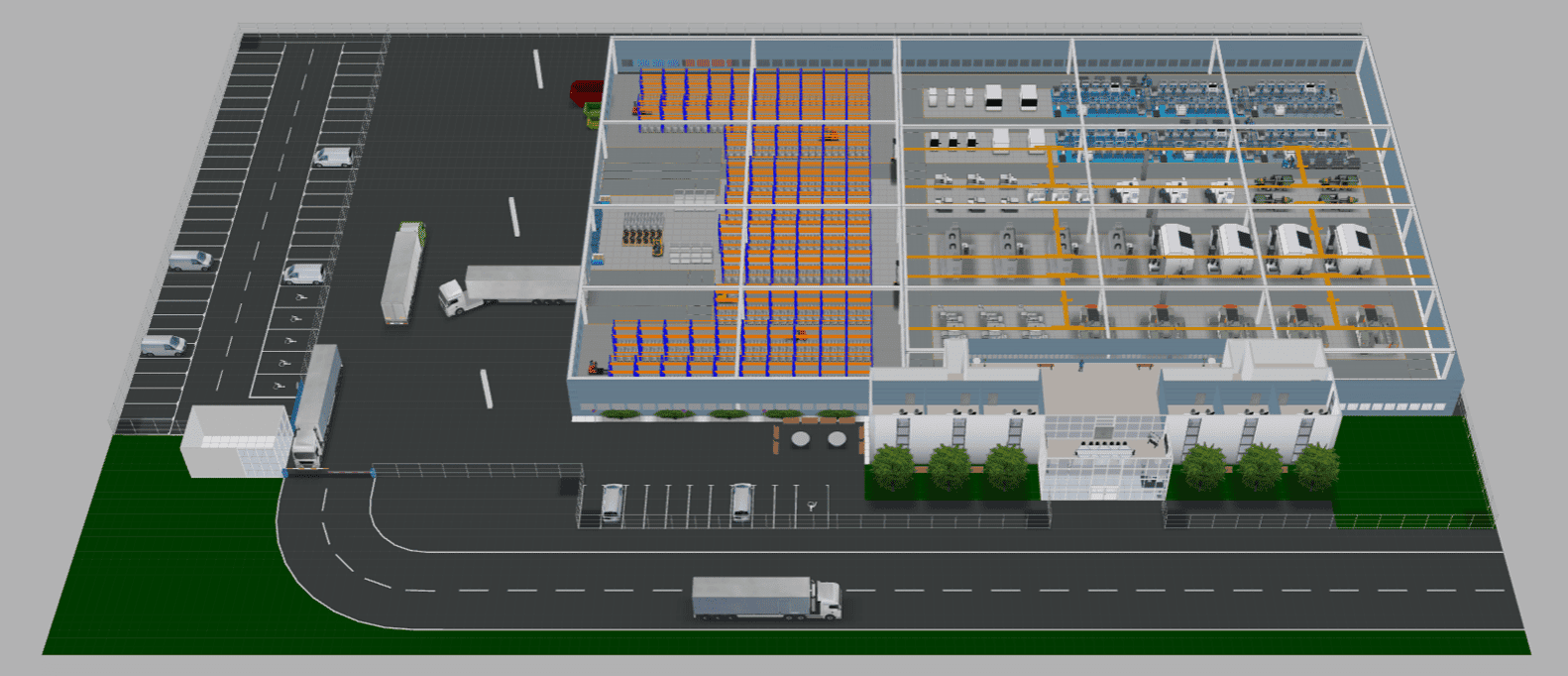

In addition to the three areas covered by this use case, an administrative wing was created at the front of the building, which is not further defined here.

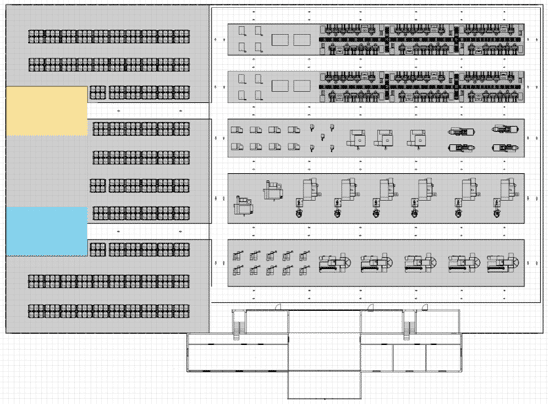

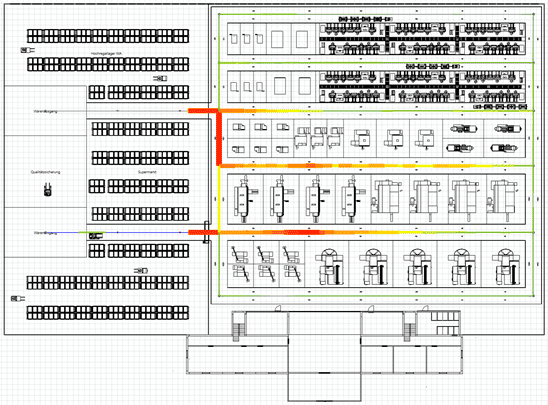

From block layout to detailed layout

We started with the detailed planning in the area of logistics. The logistics were divided into four different subareas. Incoming goods with high-bay warehouse, quality assurance, supermarket and outgoing goods with high-bay warehouse. Subsequently, the production area was defined in detail. The basis for this, in addition to the floor plan, is the created process of production, which can be taken from the value stream. The block layouts of the individual stations were designed in such a way that the material flow is as optimal as possible. The material flow will be explained in detail in a later part of the use case. Due to the different variants of compressors to be produced, the layout contains different stations, whereby not every station is required for the production of every variant.

Detailed representation of workplaces in 3D

Subsequently, the production facilities were modeled and assigned to the corresponding stations. The same applies to the leak test and the final inspection of the assembly. Assembly stations were modeled for the assembly lines, which were also integrated into the layout in this step. The plants are not necessarily the correct plants, since the model catalog of the visTABLE software contains only a limited number of variants. All plants are therefore to be regarded as schematic representations.

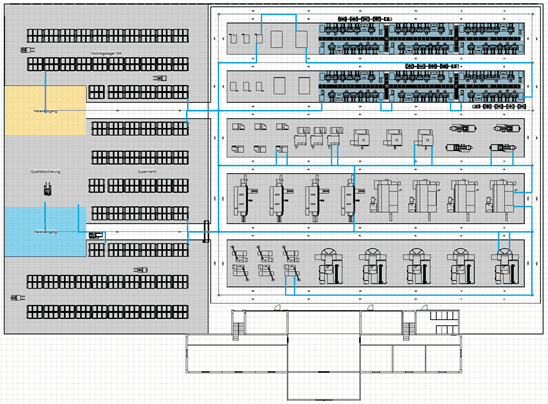

From layout to material flow analysis

Up to now, the added value of the layout developed up to this point was that it gave a better impression of the actual area required, including traffic routes, as well as an attractive visual presentation. The actual added value is now being created. Through the connection of the processes (value stream) with the layout. By physically locating the resources stored in the value stream, the material flow can now be quantified and thus subsequently optimized. All source-sink relationships are now stored and visualized in blue, as shown in the use case here.

The heat map shows potential bottlenecks

The possibilities of analysis in visTABLE consist of network load, logistics evaluation and area balance. First, the network load is considered. This is based on the utilization of the transport network by all product groups in the system. Here, the individual sections of the transport network are considered separately and assessed according to the flow rate of the products. The assessment is divided into a color scale – green to red – on the transport network. Here in the use case, it is clear that the transport route to and from the supermarket is particularly highly loaded. This is due to the high volume of transports, as the products are taken to the supermarket after the respective processing steps.

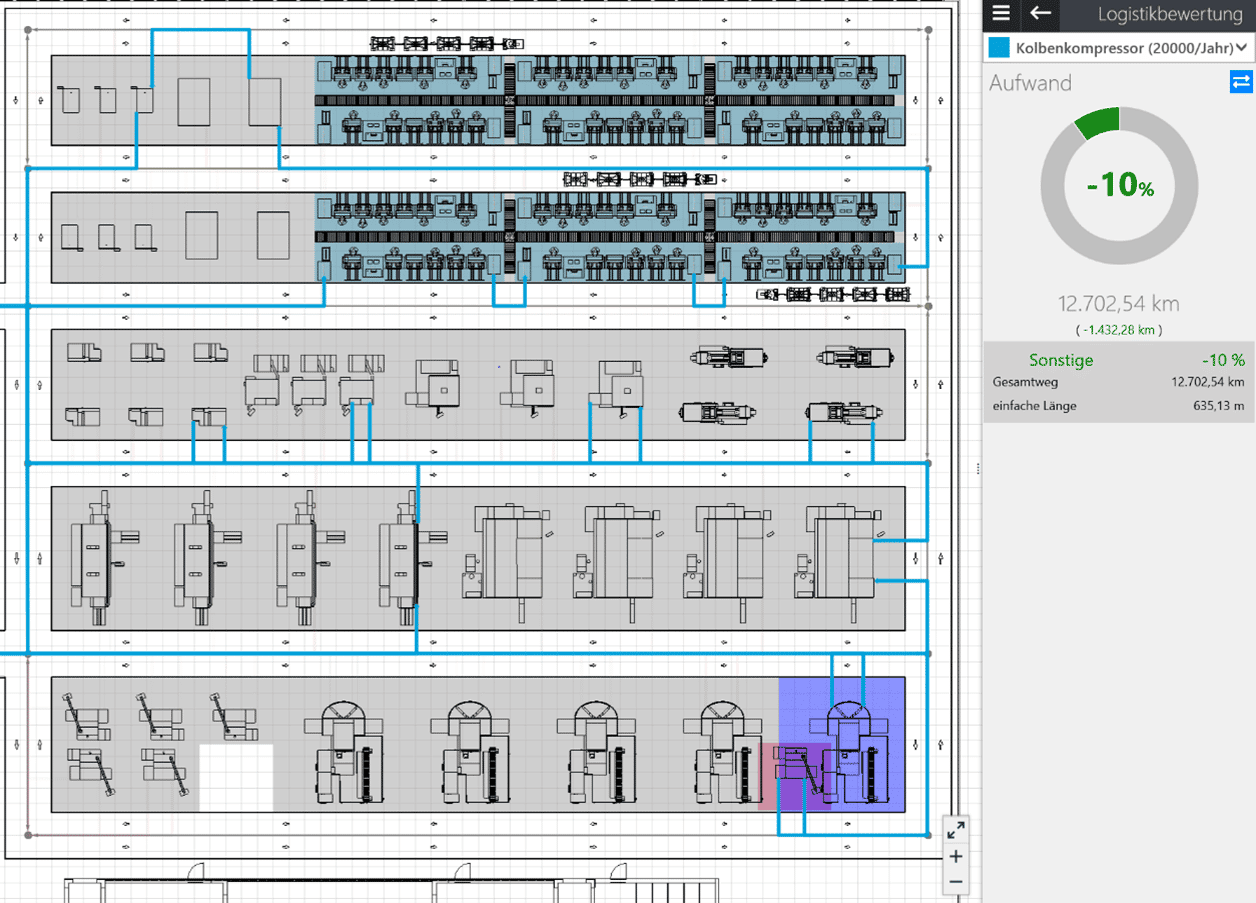

Evaluation of the material flow by means of KPIs

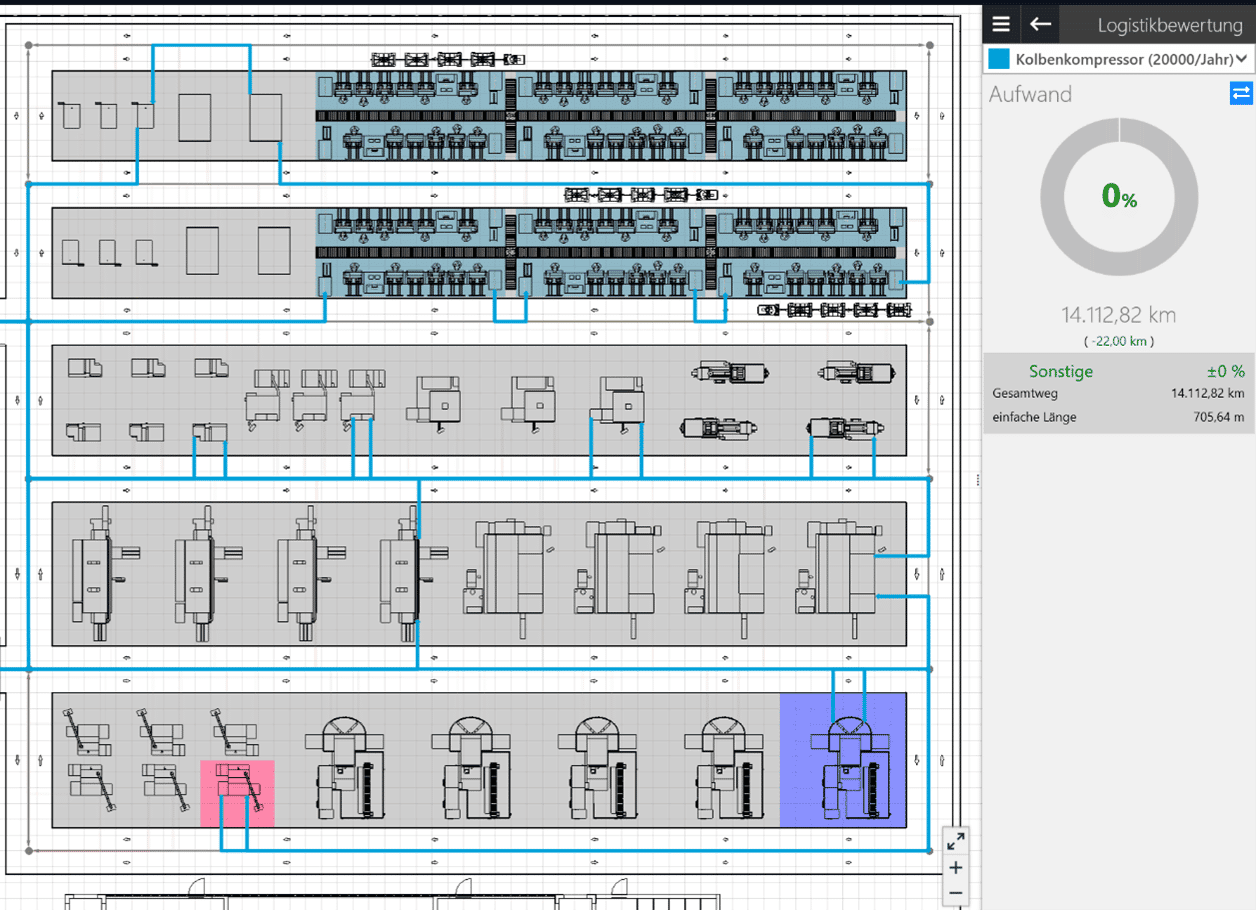

Material flow optimization in visTABLE by drag & drop

By moving individual blocks of the block layout, the material flow can be optimized easily and well illustrated. As an illustration, here in the use case, the cleaning (marked in red) has been changed in its position in such a way that the evaluation changes positively, since the cleaning has been moved closer to the machining center (marked in blue). This change is positive from a logistical point of view, since the material flow is shortened, but such a relocation of the location is not necessarily sensible or possible from a layout point of view, since various factors such as the available space play a major role here. If a station is also moved to a more distant location, for example, this would have a negative impact on the logistics evaluation.

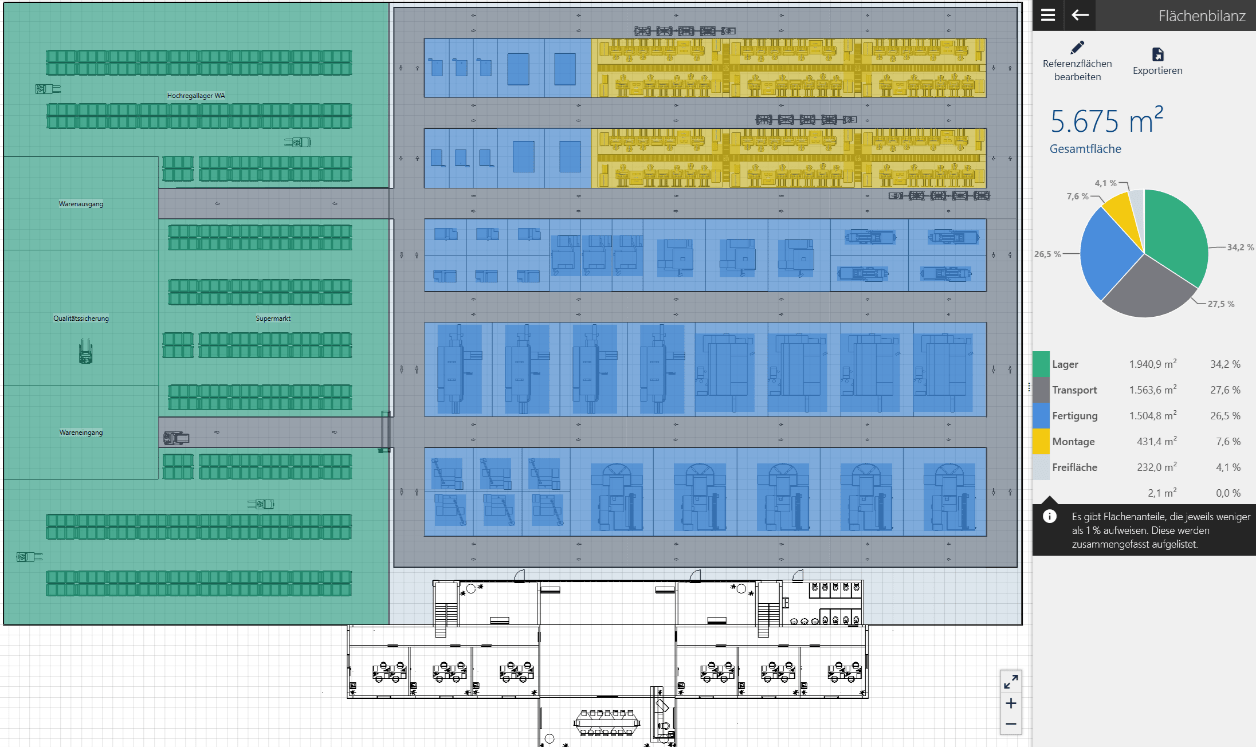

Drawing up a surface balance

Another evaluation method is the area balance. The evaluation of the area balance is a tool that is integrated in visTABLE, as are all the other evaluation methods already mentioned. For this purpose, visTABLE calculates the ratio of the reference area to the areas that were defined in the block layouts for the individual areas and presents the results in a pie chart with the area size and the percentage shares. Here in the use case, this would be evaluated as follows. The factory floor use of 5,675 m² is nearly exhausted, as the total area use is 95.9%. There is only 232.0 m² of open space. For this reason, an expansion option for the entire hall, both in the assembly and logistics areas, has been planned.

Display of results in visTABLE in 3D

Finally, to achieve the best possible realism, additional objects such as roads, parking lots, plantings and vehicles outside the factory were added to the model.

Bross Consulting Engineers offer support in planning and optimization with visTABLE

Our experts have many years of experience in planning and optimizing material flows using visTABLE. In addition to the actual creation, we show them how best to organize such a digital factory project. Furthermore, we are sparring partners for your own employees as well as for other service providers such as surveyors (e.g. for laser scans). We look forward to hearing from you!