Segmentation - types and procedure

The products of many companies are characterized by a high number of variants with low to medium quantities. The goal of segmentation of manufacturing and assembly is to reduce the complexity of the variant diversity and to structure it into suitable units. This requires an analysis of the product assemblies (e.g. by exploding the bill of material) as well as the assembly or manufacturing sequence. A suitable tool for this would be the assembly priority graph or the routing.

What are the types of assembly and manufacturing segmentation?

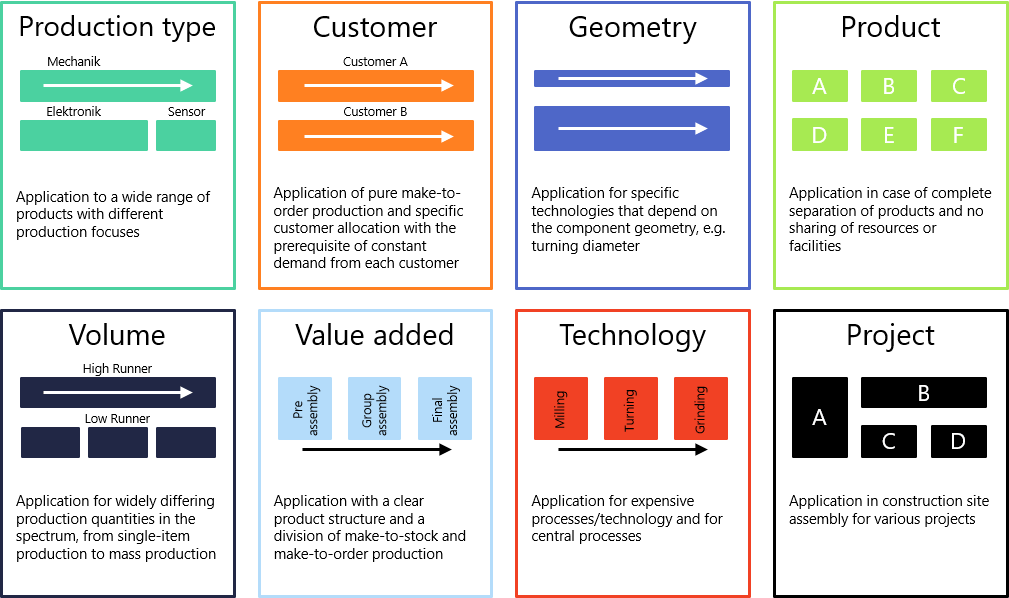

In principle, 8 types of segmentation for manufacturing and assembly can be distinguished by the above procedure:

- Manufacturing type: application to a wide range of different products with different focal points in manufacturing

- Customer: Application of pure contract manufacturing and specific customer allocation with the prerequisite of a constant demand at each customer

- Geometry: Application with specific technologies that depend on the part geometry, e.g. turning diameter

- Product: used when there is a complete separation of products and no sharing of resources or equipment

- Volume: Application for widely varying production quantities in the spectrum, from one-off production to mass production

- Value added: Application with clear product structure and a division of make-to-stock and make-to-order production

- Technology: Application with expensive processes/technology and with central processes

- Project: Application in site assembly for different projects