Production system - methods, principles and standards

Production system is on the one hand a term from the area of the production economy. This term covers systems and subsystems in which production takes place, for example entire plants as well as individual, value-creating parts of plants such as factories, production segments, workshops or production lines. On the other hand, a production system is a set of coordinated strategies, principles and methods for production within a particular company. The best-known example is the Toyota production system, which is based on the fundamental idea of avoiding waste and uses methods such as continuous improvement processes, kanban or just-in-time concepts for this purpose. The production management concept is based on the idea that production processes can be described as systems, such as input/throughput/output systems. The input represents goods that are made available to the system from outside for transformation (labor, raw materials, electricity, heat, etc.). The throughput is the actual transformation process, i.e. the change of the processing objects. The output is the release of objects from the production process to the environment, which either leave the company or are further processed. This includes, on the one hand, the release of manufactured or changed processing objects, heat or generated electricity, and on the other hand, unwanted objects, such as waste gases, waste water, hazardous waste or chips.

Different types of production systems compared

Production systems are distinguished in the literature in particular according to production types. Depending on whether, for example, single-item, series or mass production or workshop or flow production is involved, different types of planning problems arise. Solving these problems and thus configuring and controlling production systems as efficiently as possible is the task of production management.

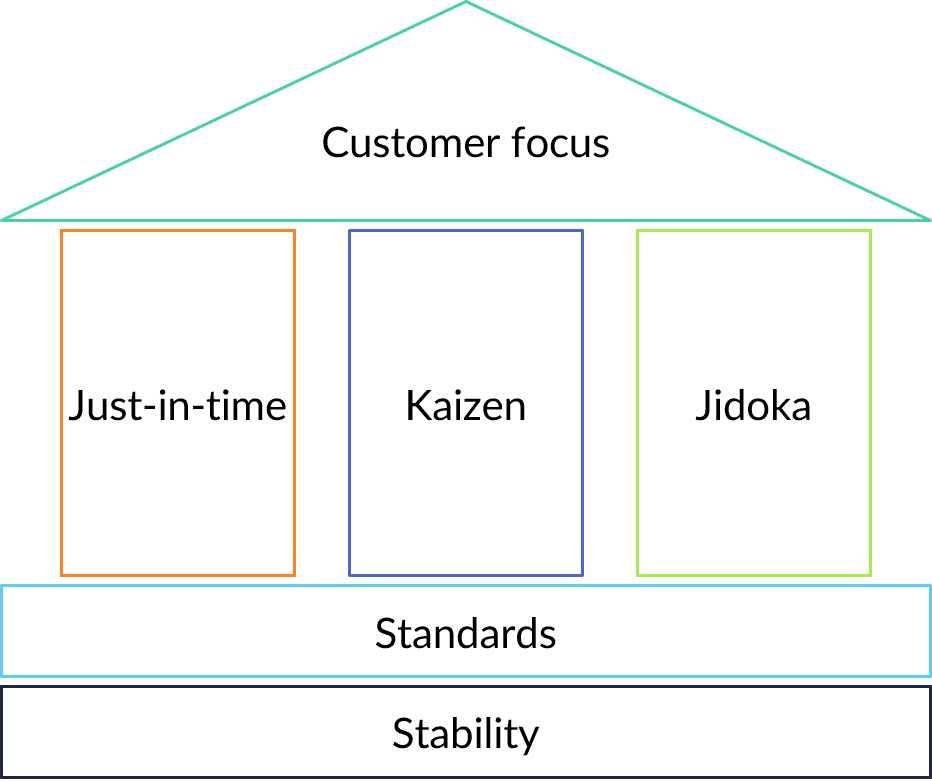

The Toyota Production System

Individual companies have developed their own production systems in which they describe the general principles, standards, methods and tools that apply to the organization and the way of working and producing in their company worldwide. The best known of these production systems is the Toyota Production System (TPS). In the meantime, many companies, especially in the automotive industry, have developed their own production systems, most of which are based on the principles developed by Toyota. Many of the principles, methods and tools first introduced by Toyota also underlie lean management.

Contact us

You need methodical input for your production system or want to reorganize it for your company? Then contact us.