Kanban - definition and function

Kanban is the Japanese word for card or character. Tominaga provides the following definition in 1996:

"A kanban is a carrier of information that runs with the product through manufacturing and contains the necessary work instructions. But a kanban can also trigger a supply of new material. So there are different types of kanbans. In the context of a system, kanbans are used to ensure that the required goods are produced in the required quantity at the right time"

The basic principle is quite simple: instead of compensating for fluctuations in demand by means of inventories and thus keeping the production process as uniform as possible (push production), the Japanese idea relies on demand orientation. This is because with push supply to production, the upstream manufacturing plant simply forwards the material to the downstream operations on a specific date. This leads to unnecessary inventory in advance of the next manufacturing step.

With Kanban, on the other hand, the downstream operation only takes parts from the upstream operation in the required quantity and at the required time. If new material is required, the consumer requests the supplier to deliver via the system. When a signal arrives, such as a card, the supplying point begins to provide the specified material and place it in a standardized container. The container with the card is then delivered to an agreed point. The recipient consumes the delivered parts up to a minimum stock level and then sends the kanban card back to the supplier.

What are the different types of Kanban?

Variations of all kinds are possible because the process is to be adapted to the respective circumstances. In the course of the adaptation to new requirements and the continuous improvement of the system, different Kanban classes emerged. Already in 1980 one distinguished in Japan the

- Material Kanban for the production and supply of material returned after a container has been opened

- Signal kanban as material kanban, but returned only when a certain amount is consumed from the container

- Transport Kanban, as a request to move a specific material from a storage bin to a staging area.

- Limited kanban, as a material kanban that is invalid after a specific production quantity

What are the goals of Kanban?

In the meantime, there are a variety of variations depending on the philosophy. However, the goals to be achieved with an introduction of Kanban are similar. Goals that are measurable and achievable with the introduction of Kanban:

- Reduction of lead times

- Inventory reduction

- Reduction of scrap and waste

- Simplification of the organization

- Increase flexibility

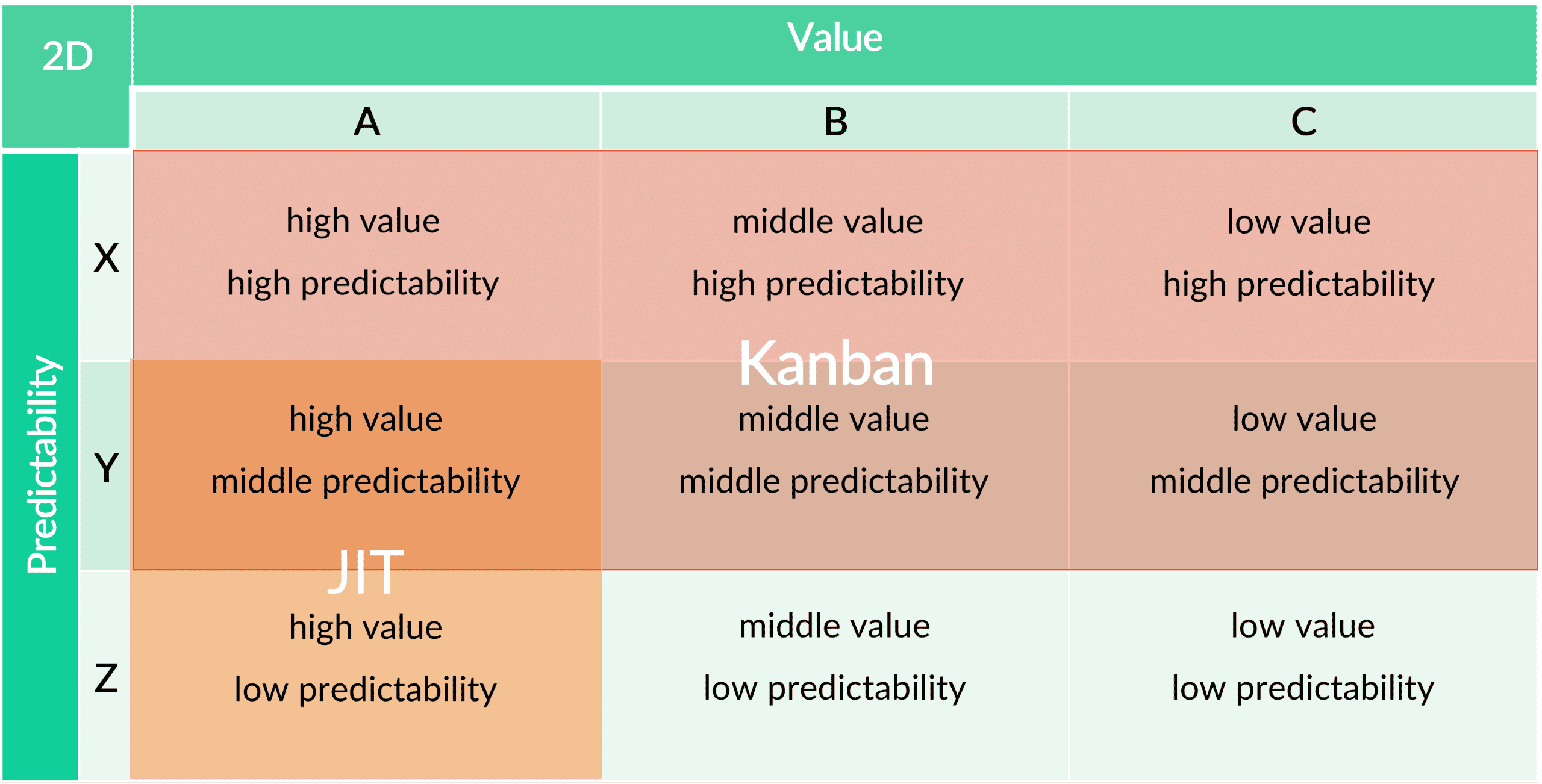

ABC analysis

The decision about the selection of a product for the Kanban supply can be made with different methods. The ABC analysis is a planning and determination method, which is used among other things in the context of the material management. It examines, how strongly a certain characteristic is concentrated on the individual elements of a considered quantity. With the help of the ABC analysis a division of the material assortment takes place into A-parts, B-parts and C-parts according to their relative value portion of the total value of the procured materials. A quantity – value – relationship investigation takes place. This investigation is based on the realization that usually the material requirement structure of an enterprise is characterized in such a way that a regularly small portion of the used material types (A-parts) forms the main portion of the value of the altogether procured materials. Material types with a lower share of the total value but a higher quantity share are classified as B – and C – parts.

Looking at the consumption of individual materials over a longer period of time, it can be seen that on the one hand there are materials whose consumption is almost constant, on the other hand materials whose consumption is subject to certain fluctuations and finally those with completely irregular consumption.

XYZ analysis

Accordingly, the materials weighted according to the ABC method could also be classified according to the predictive accuracy of their consumption. Here, the classification symbols mean the following:

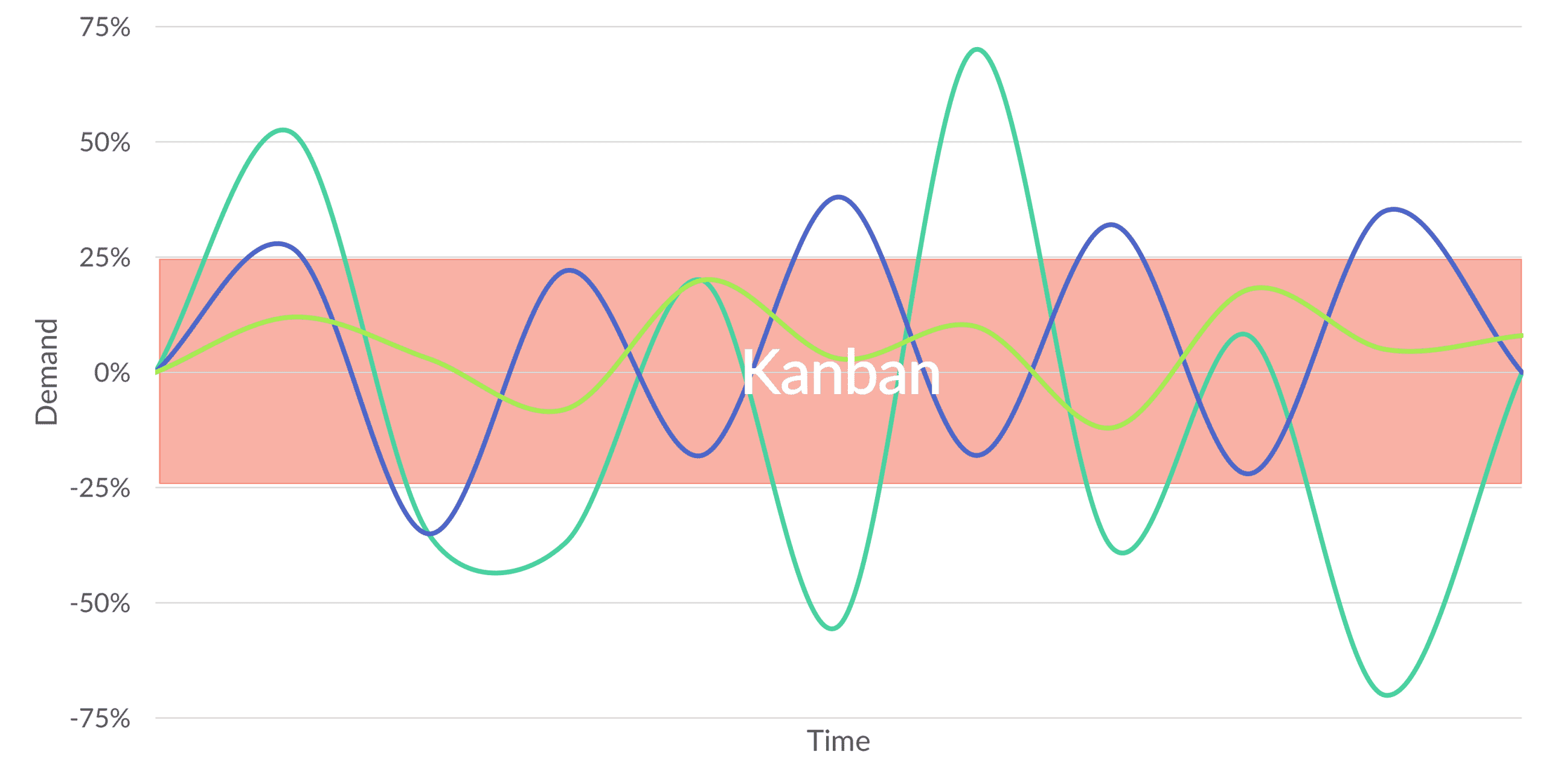

X-parts: Consumption is constant with only occasional fluctuations; high prediction accuracy.

Y-parts: Consumption is subject to greater fluctuations, is trended up or down, or is subject to seasonal fluctuations; medium predictive accuracy.

Z-parts: Consumption is completely irregular; low prediction accuracy.

The execution of the ABC – analysis in connection with the XYZ – analysis is the condition for the determination of the kanban suitable products. An application of the Kanban – system offers itself for all products with a rising consumption process (X-products and partly Y-products). The quantitative fluctuation interval in a planning horizon of one week +/- 5% and one month +/- 30% should not be exceeded here. The valency of the products (ABC analysis) affects thereby the characteristic of the Kanban. Favorable C articles, for example, are realized in larger container quantities with a high safety quantity as a kanban cycle. Expensive A articles are recorded individually in kanban cycles.