Digital twin - application and advantages

The digital twin is suitable for use in logistics and factory planning. It is a digital method for improving your planning processes. A digital twin is the virtual mirror image of a machine, a production line or a complete factory. This digital replica, which can be an entire production facility, not only supports the analysis, design or evaluation of processes, but also helps in the overall planning of production or logistics processes.

Act instead of react with digital twin

The knowledge we gain from a digital twin enables us to react in real time to any conceivable situation. For this purpose, the collected operational data is processed, understood, evaluated and used. To realize this, raw data is evaluated using data analytics and simulations, and forecasts are made. This not only facilitates and improves the planning of new plants, but also enables service to be raised to the next level. Through the simulations, maintenance cases or upcoming maintenance can be predicted, which facilitates the implementation and reduces costs.

Advantages in planning through digital twins

Especially in process design, however, the digital twin brings enormous advantages. For example, the material flow can be optimally designed without having to restructure plants and machines in reality. This not only saves time and costs, but also shows the best possible production flow. This applies both to the store floor level and to the planning process.

Towards industry 4.0 with the digital twin

The digital twin also brings with it a major leap towards industry 4.0, as it makes a significant contribution to the digitization of your company. In a further step, it is possible to act even more digitally by “viewing” the digital twin “live” in the empty production/logistics hall via AR & VR applications. Here, first impressions are created and positioning or processes can be further adapted or optimized.

In summary, it can be said that the concept of the digital twin can be developed into the perfect business process and is indispensable as digitization in production and logistics continues to advance.

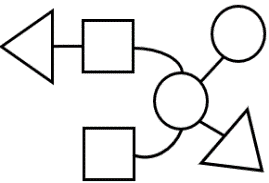

Component twin

The basic unit of the digital twin is called a component twin and represents a replica of a single component of the twin, which has a key function. The definition of the partial twin is the same as that of the component twin, but the partial twin refers to components with an irrelevant meaning.

Asset twin

If two or more individual components work together, this is referred to as an asset. The asset twin is the next level up from the digital twin. With the help of this, the interactions of the individual components can be examined, the interaction analyzed and potential for improvement made apparent.

System twin

The system twin, or unit twin, combines several asset twins into an overall system. This system provides information about the interactions between the asset twins and can be used to identify potential for performance improvements.

Process twin

The process twin represents the macro level of the digital twin. It combines several systems with each other and shows how the systems or all units work together and whether this happens synchronously. For example, the process twin can represent an entire production plant. From this, the greatest possible efficiency is to be achieved. It can also show how delays from one system affect another. Thus, the change in overall effectiveness can be analyzed based on different scenarios.

Difference between a digital twin and a classic simulation

Already the definition of simulation and digital twin show essential differences. Nevertheless, it must be clearly delineated which of the two it really is. The classic simulation is rather used for new planning, where no current status is available. For this reason, simulations can only be used to make theoretical predictions about potential events when changes occur. Furthermore, the integration of real-time data is quite possible, but in reality this turns out to be very complex. A Digital Twin, on the other hand, can show what is happening in the present moment and in the future within the processes of the physical twin. For this reason, the Digital Twin is more likely to be created for existing plants. Nevertheless, it should be noted that a classic simulation and a Digital Twin are only as good as the quality of the data they work with.

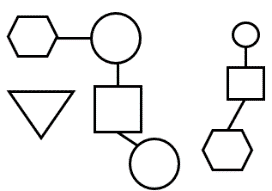

Digital model

The Digital Model is generally considered to be a digital replica of an existing or planned object that does not perform any automatic exchange of data between the physical object and the digital object. The model has more or less information about the physical object and can contain mathematical models of new products or other models of the physical object. Data exchange is exclusively manual, whereby the change of state of the physical object does not affect the digital counterpart and vice versa.

Digital shadow

The Digital Shadow can generally be seen as a virtual replica of all relevant data from a production, development and areas within the system boundary. In contrast to the digital model and the twin, there is a one-way data flow between the physical and digital object. A change of state in the physical object causes a change in the digital counterpart, but not vice versa.

Digital thread

The digital thread describes a kind of connection between all submodels and extends over the entire product lifecycle. It also acts as an interface for these and can integrate information from other IT systems (e.g., CRM). It also ensures traceability and, in the event of problems with a component, makes it possible to search backwards for problems and determine the cause. This enables optimization across the entire value creation process.

System

A system can generally be seen as a construct of elements that are related to each other. The system boundary acts as a boundary between the system and the system environment. A system should be considered thereby however never generally, but only in different kinds of systems. Examples for systems would be: